INJECTION OF THERMOPLASTIC AND TOOLING FOR INJECTION MOLDS.

OUR COMPANY

We are a plastics and technology industry located in the state of São Paulo / Brazil.

Having operated in the product and technology injection segment for 37 years, we have the experience and technical knowledge to deliver to our customers the best in plastic injection services, project development and injection tools, through product design in technical integration parts and PCBs. We also have a tooling service, in which our highly specialized professionals deliver high-quality tools, molds and dies, together with our extensive product assembly line, operating and serving various segments of the technical parts market. Highly experienced and qualified, Marppel has been building relationships with national and international companies.

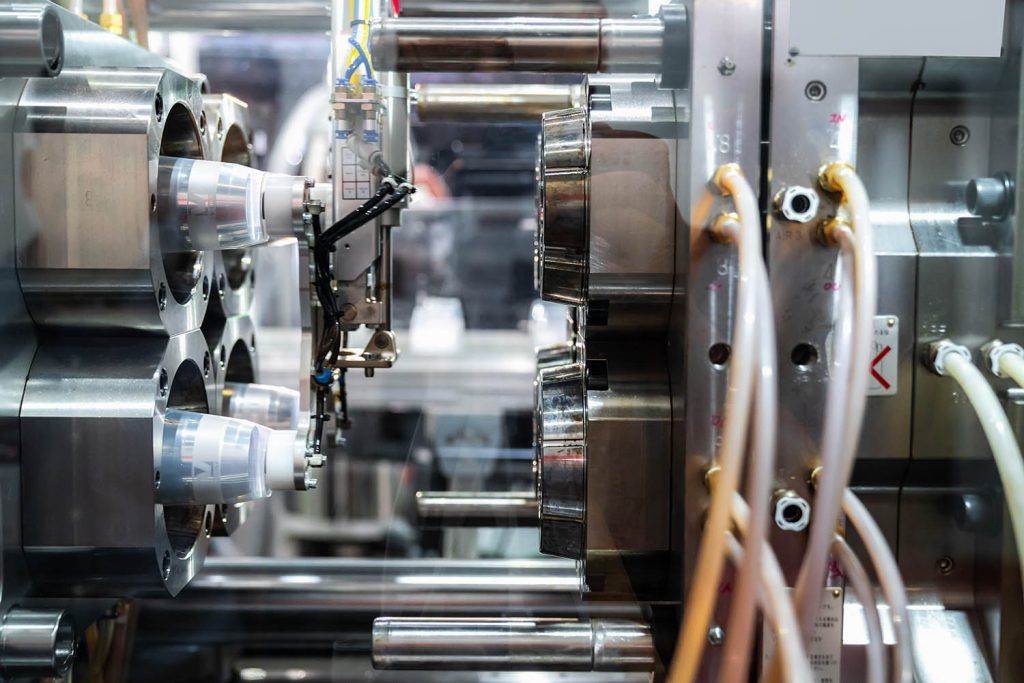

Injection of

Plastics

Injection molding machines with different clamping force capacities producing parts with high technical standards for the development of various materials, from commodities to engineering plastics and PVC/CPVC with speed, precision and safety.

Tool shop

Mold and Dies

Own mold and die tooling to ensure agility and less machine downtime.

We have an equipped tooling sector that allows us to carry out maintenance and build molds and dies for the most diverse industrial segments, in a variety of applications of different sizes.

Project Development

With a multidisciplinary team of professionals from the areas of design, engineering, business and marketing who are constantly updating their skills, Marppel has helped to consolidate the image of numerous national and international companies, delivering products that are benchmarks in their segments to the market. Projects that are born from an idea or need and are consolidated after product design development and rapid prototyping.

Assembly line

We offer a wide and specialized assembly line where the production process is usually adopted and is the most suitable for manufacturing products in large quantities. The idea behind this process is to divide the work into stages that take place on a production line, where each employee or team focuses only on their own stage.

Responsible Plastic Injection

We supply injection molded plastic parts to a range of well-known industries

for its technical and quality requirements.

We can be your main partner in the manufacture of injected parts.

Policy of

QUALITY AND EXCELLENCE

Continuously channel efforts towards seeking constant and full customer satisfaction through continuous improvement. Maintain the improvement of our human resources and processes, resulting in quality products and services, meeting regulatory and stakeholder requirements.

We serve all over the world

National Territory

Hundreds of customers throughout Brazil trust the quality of Marppel products and services. Our quality is certified, which guarantees our total quality policy in 100% of our services.

Clients

International

Marppel is located close to the American and European continents, bringing many benefits related to lower freight costs and easy and fast logistics experience.

DEVELOPMENT STRATEGY

CALCULATION OF VALUE PER MACHINE HOUR

STRATEGY FOR SHORTER DEVELOPMENT TIME

TOTAL INVESTMENT REDUCTION PLAN

MACHINES FROM 60 TO 520 TONS

MULTI-CAVITY MOLDS

WE DEVELOP YOUR PRODUCT

• INDUSTRIAL PROJECT DESIGN;

• RAPID AND PRECISION PROTOTYPING;

• TOOLS AND MOLDING;

• PLASTIC INJECTION OF TECHNICAL PARTS;

• PLASTIC, ALUMINUM OR ZAMAK INJECTION;

• GENERAL ASSEMBLY;

• INTEGRATION PARTS AND PCB;

• INDUSTRIAL LOGISTICS PLANNING;

• EXPORT AND IMPORT;

• NATIONAL AND INTERNATIONAL SERVICE.